DX30+

DX30+ MOUNTED FERTILIZER SPREADER: EASE OF USE AND AUTONOMY

3 strong arguments:

- Integral drainage for ZERO “dead” volume

- No sensitivity to fertilizer hopper load

- Instant opening/closing without jamming

Once the chute is in place, simply measure the distance indicated on the ruler and weigh the result. This same ruler will then give you the correct trap setting.

3 strong arguments:

- Maximum accessibility

- Quick-fit trunking… keyless

- No cumbersome handling.

With the DX30+, it’s :

- 36 m with good quality fertilizer

- 28 m for all fertilizers.

Graduated sectors redesigned for your comfort:

Large sectors for error-free width adjustment, and full visibility of graduations regardless of the number of hectares spread.

Developed on the DPX range and perfected on the DX range, our width control is the benchmark for centrifugal spreading. It works by modifying the point at which the fertilizer falls onto the disc, using an exclusive outlet chute.

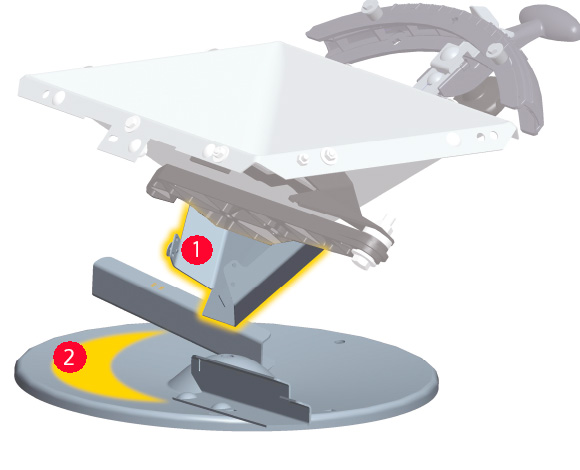

1. The chute: inclined, it guides the fertilizer precisely onto the tray.

2. The drop point: this is the essential device for guaranteeing large widths. Its adjustment does not require any change in the rotation speed of the plates, nor any touching of the ejection blades.

100% electric

- Electric control from the cab without leaving the tractor

- No hydraulic distributor

Zero broken grain

- In keeping with the logic of modifying the drop point

- No alteration of your fertilizer

A recognized weighing system with dual weighing chassis, ultra-capacitive 10T load cell and 4 leaf springs.

The benefits of weighing :

- No more repeated flow tests!

- 5-10% fertilizer savings

- In-cab weighing information display

The SKY weighing system: precision equipment

- Aim for kilo-accuracy with automatic flow adjustment from the cab.

- A single factory-calibrated “all stainless steel” weighing cell, fully protected by the weighing frame, rather than a multiplication of reference points.

- An inclinometer integrated into the electronic board guarantees high measurement accuracy on both slopes and inclines.

DX30 ECONOV competitive section cut-off through flow control

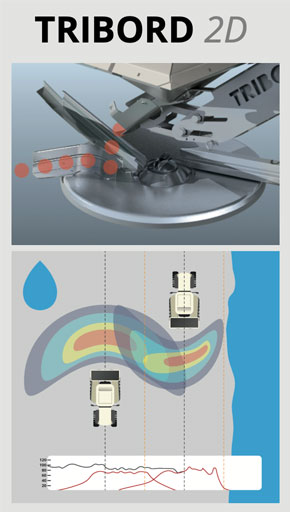

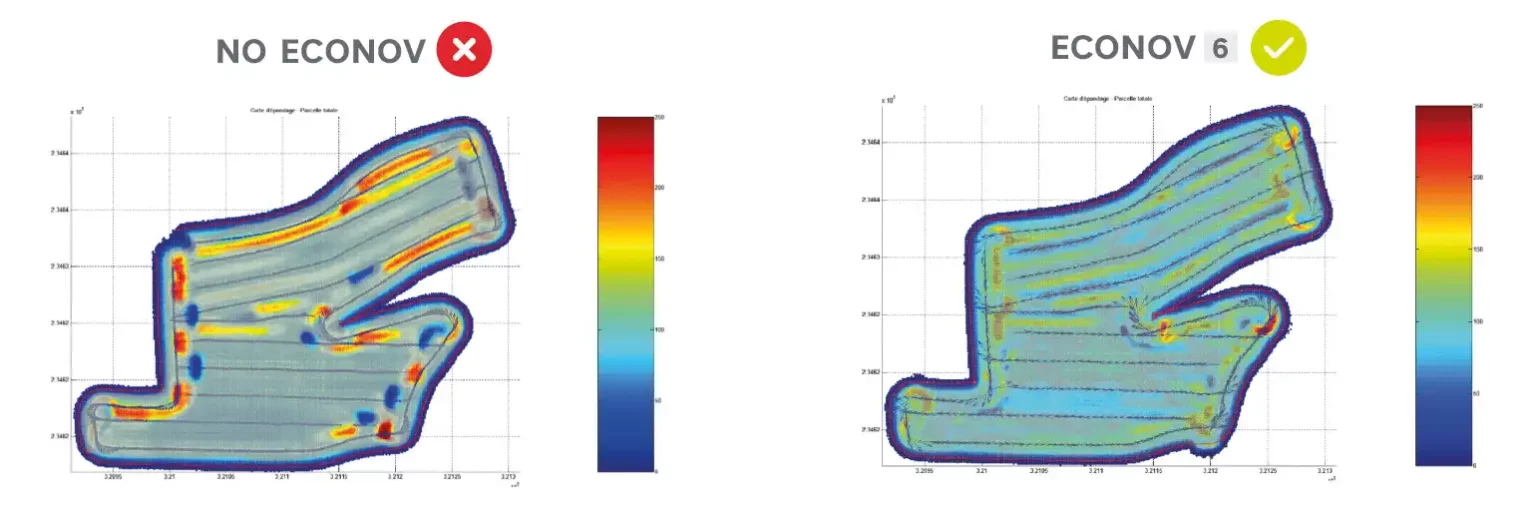

The ECONOV 6-section cutterbar minimizes fertilizer overdosing on working widths from 18 to 36 m.

For GPS optimization of fertilizer distribution on field edges and in corners, action on the “flow” parameter is a relevant response for the DX30+ distributor, as it avoids overdosing and significantly improves field distribution.

The eco-evaluation study carried out by IRSTEA and KEREVAL shows fertilizer savings of 7% and a reduction of more than 20% in under- and over-dosed areas.

| TYPE | DX 30+ | DX 30+ | DX 30+ | DX 30+ | |

|---|---|---|---|---|---|

| Working width | 12-36 m | 12-36 m | 12-36 m | 12-36 m | |

| Flush hopper capacity | 1500 l | 2150 l | 2350 l | 3000 l | |

| Overall width | 2,48 m | 2,48 m | 2,98 m | 2,98 m | |

| Loading dimensions | 1,23 x 2,40 m | 1,23 x 2,40 m | 1,23 x 2,80 m | 1,23 x 2,80 m | |

| Loading height | 1,06 m | 1,27 m | 1,29 m | 1,49 m | |

| Weight (indicative) weighed version | 305 kg | 350 kg | 355 kg | 400 kg | |

| Payload | 3000 kg | 3000 kg | 3000kg |

|

IN PICTURES

SPREADER

Mounted spreaders