X40+ AND X50+

X40+ AND X50+ MOUNTED FERTILIZER SPREADERS: OPTIMIZE YOUR FERTILIZER APPLICATIONS IN FIELD CROPS

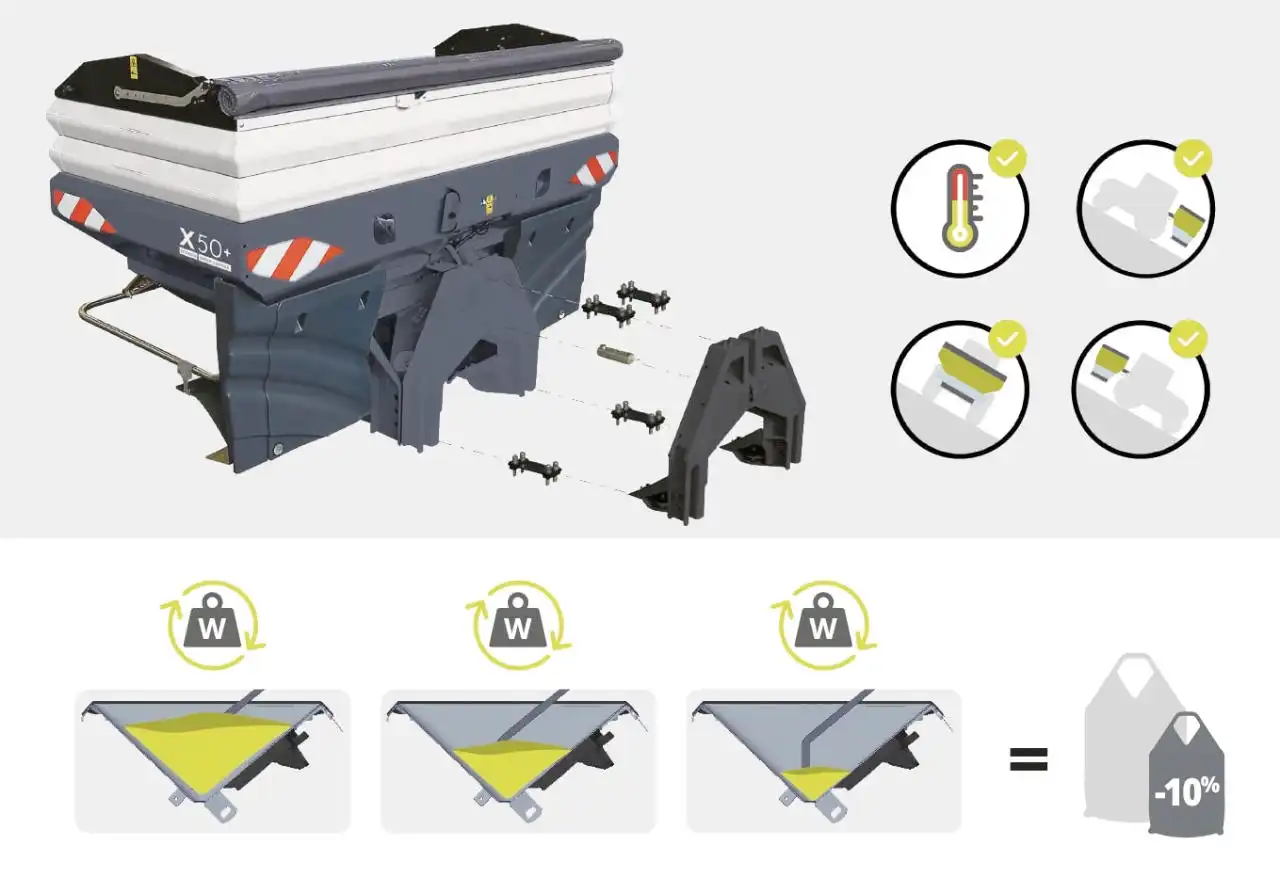

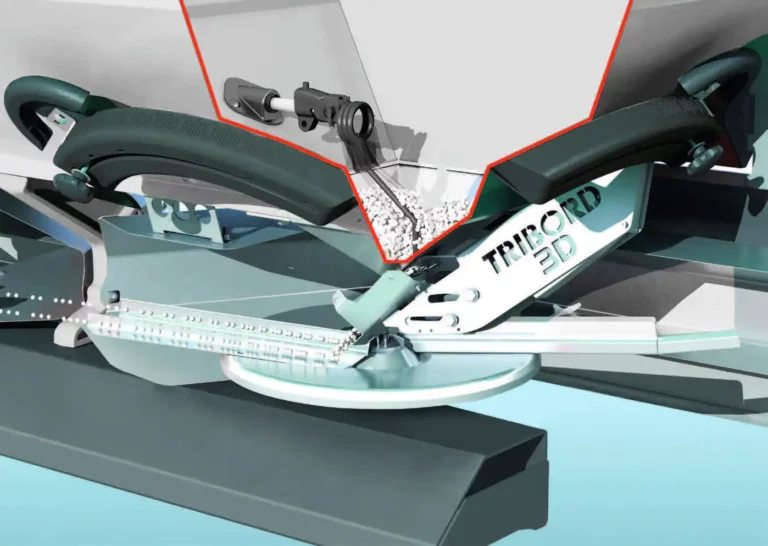

A recognized weighing system with dual weighing chassis, ultra-capacitive 10T load cell and 4 leaf springs.

The benefits of weighing :

- No more repeated flow tests!

- 5-10% fertilizer savings

- In-cab weighing information display

The fruit of 30 years’ collaboration with IRSTEA (formerly CEMAGREF), our knowledge of the fertilizer table is unrivalled:

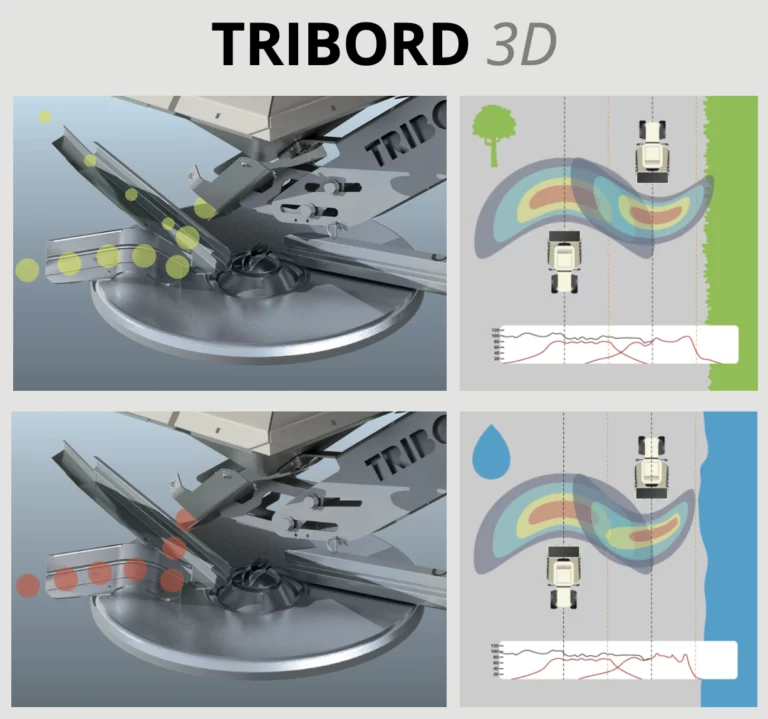

- Control of large widths, taking into account all groundwater parameters

- Fertilizer distribution by height, width and depth

The development of the CEMIB test bench gave us a 3D view of the actual fertilizer slick.

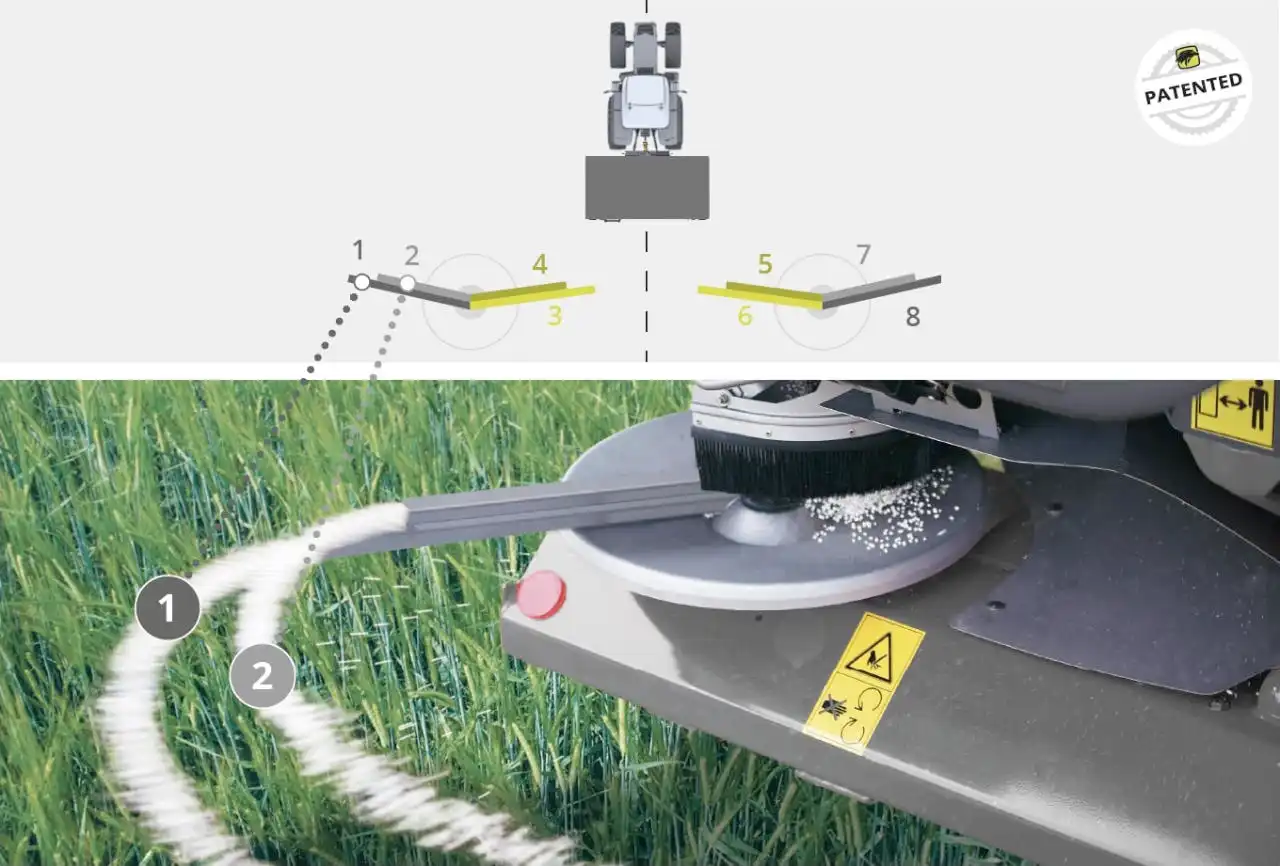

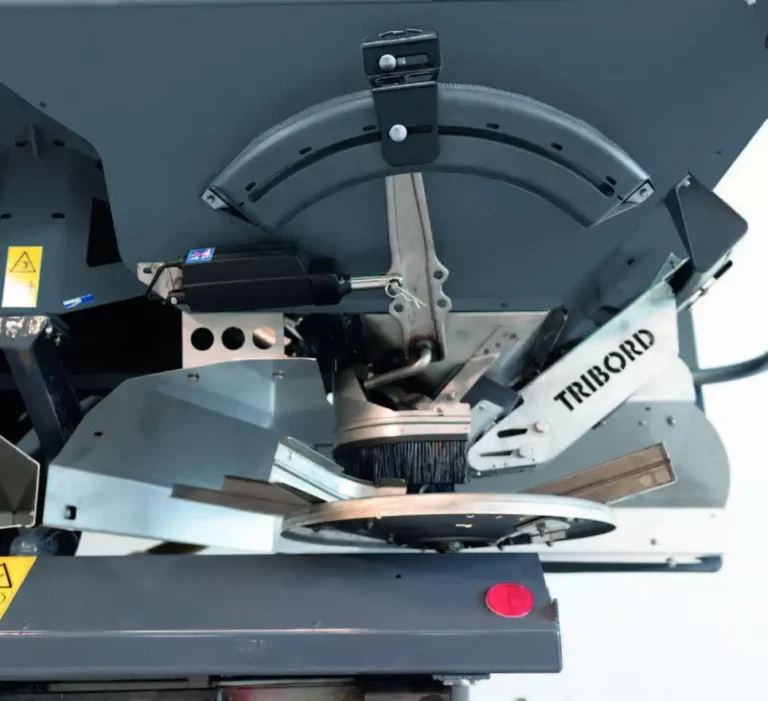

Epsilon System patent enables multi-coating, guaranteeing optimum distribution

4 “pure” layers of fertilizer per tray :

- Rigorous two-stream channelling of pellets as soon as they reach the paddles

- Maintains this distribution throughout centrifugal acceleration, regardless of flow rate/ha

Digital technology for complete collections

- Optimum crossover between outward and return flow sheets

- Even spreading across very wide widths

- Width adjustment by “infinitely” adjustable chute by changing the feed point on the disc

- Rely on your safety

- No sprockets, plates or even blades to handle, especially when spreading late. Work width adjustment is carried out at a safe distance from moving parts!

1. Oscillating flow regulator

Better than an agitator, it’s self-destructing on headlands and field ends!

2. Record flow

Up to 520 kg/min

Whether your field border touches a watercourse, a house, a road or a cultivated plot, choose the edging method that’s right for you!

100% electric

-

- Electric control from the cab without leaving the tractor

- No hydraulic distributor

Zero broken grain

-

-

- In keeping with the logic of modifying the drop point

- No alteration of your fertilizer

-

- Customise your machines

- Save your settings

- Save your work

Available on the Google Play Store and App Store, create your account now!

| TYPE | X 40+ | X 40+ | X 40+ |

|---|---|---|---|

| Working width | 12-44 m(1) | 12-44 m(1) | 12-44 m(1) |

| Flush hopper capacity | 1900 / 2050 l | 2500 / 2650 l | 3000 / 3200 l |

| Overall width | 2,70 m | 2,70 m | 2,98 m |

| Useful loading width | 2,31 m | 2,31 m | 2,81 m |

| Loading height | 1,23 m | 1,41 m | 1,52 m |

| Weight (indicative) weighed version | 540 kg | 570 kg | 585 kg |

| Payload | 3000 kg | 3000 kg | 3000 kg |

| Loading depth | 1,17 m | 1,17 m | 1,17 m |

(1) For optimum working quality, choose the blade set best suited to your application: EV 12-18 m, EV 18-28 m, EV 24-36 m

| TYPE | X 50+ | X 50+ | X 50+ |

|---|---|---|---|

| Working width | 24-50 m* | 24-50 m* | 24-50 m* |

| Flush hopper capacity | 2400 / 2600 l | 3200 / 3400 l | 4000 / 4200 l |

| Overall width | 2,98 m | 2,98 m | 2,98 m |

| Useful loading width | 2,81 m | 2,81 m | 2,81 m |

| Loading height | 1,26 m | 1,44 m | 1,62 m |

| Weight (indicative) weighed version | 670 kg | 705 kg | 530 kg |

| Payload capacity | 4000 kg | 4000 kg | 4000 kg |

| Loading depth | 1,17 m | 1,17 m | 1,17 m |

* For optimum working quality, choose the blade set best suited to your application: EV 24-36 m, EV 32-44 m or EV 40-50 m.

IN PICTURES

SPREADER

types